At Oak Ridge National Lab, under the guidance of Som Shrestha, Daniel Howard, and Shen Zhenglai, I explored the thermal properties of phase change materials (PCMs) for water heating systems. Using Frontier, the world’s fastest supercomputer, phonon group velocities, scattering rates, and band gaps were calculated to understand how these materials absorb and release heat. The goal was to see how PCMs could make water heating more energy-efficient and cost-effective. This hands-on experience gave me a chance to connect what I’d learned in physics to real-world applications, and it showed me how material science can solve practical problems in innovative ways.

Steps Taken

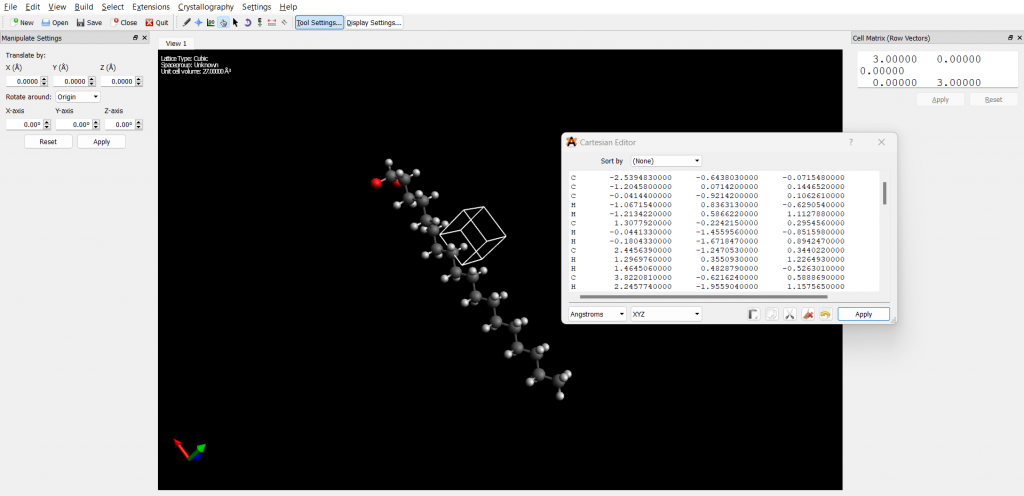

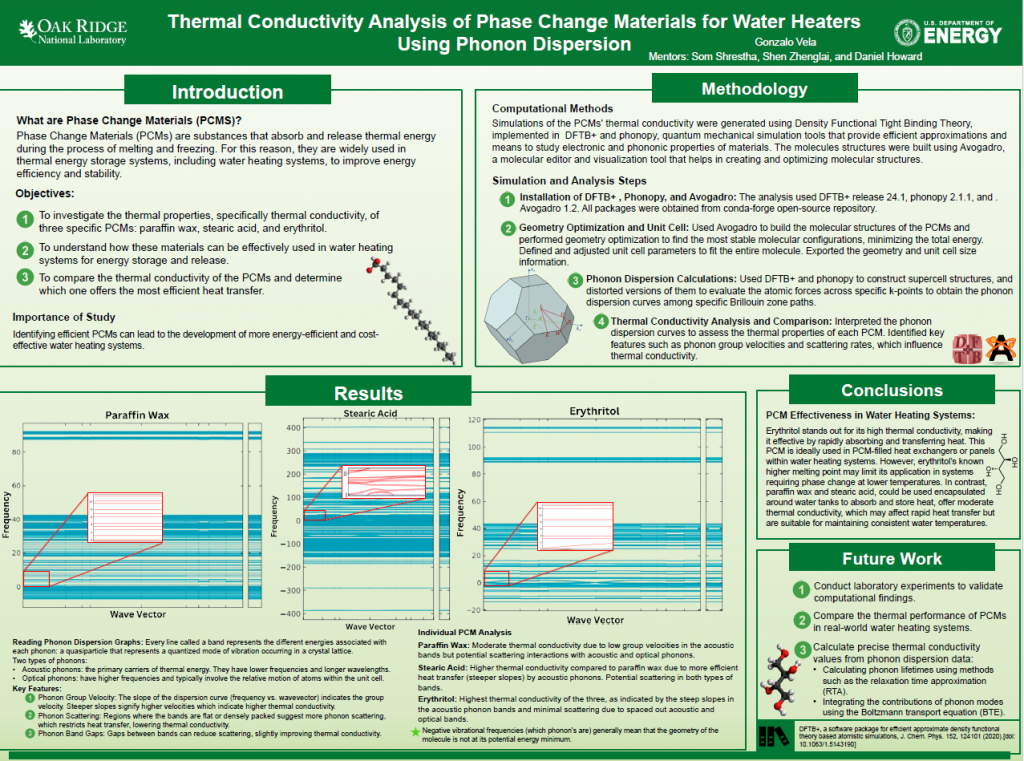

- The appropriate tools and simulation programs were installed and test simulations were run to ensure validity. Programs used: DFTB+, Phonopy, Avogrado.

- Geometry Optimization: The molecules structures for Stearic Acid, Paraffin Wax, and were built and optimized using Avogadro, a molecular editor and visualization tool that helps in creating and optimizing molecular structures.

3. Through Frontier utilized DFTB+ and phonopy, quantum mechanical simulation tools that provide efficient approximations and means to study electronic and phononic properties of materials to construct supercell structures.

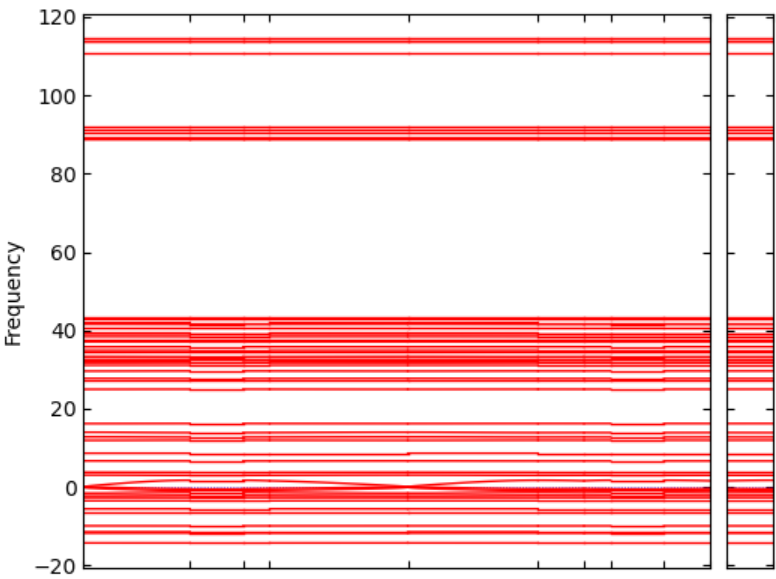

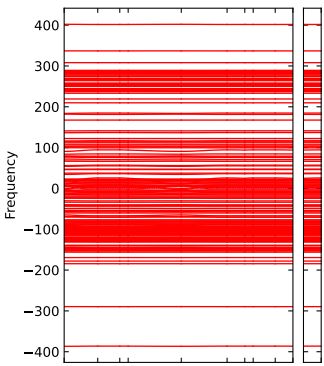

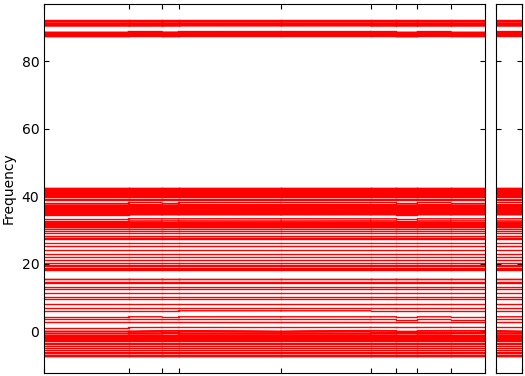

4. Made distorted versions of the supercell structures to evaluate the atomic forces across specific k-points to obtain the phonon dispersion curves among Brillouin zone paths. *Negative vibrational frequencies (which phonon’s are) generally mean that the geometry of the molecule is not at its potential energy minimum.

Erythritol Dispersion Curve

Stearic Acid Dispersion Curve

Paraffin Wax Dispersion Curve

5. Interpreted the phonon dispersion curves to assess the thermal properties of each PCM. Identified key features such as phonon group velocities, band gaps, and scattering rates, which influence thermal conductivity.

6. After analysis, Erythritol stands out for its higher thermal conductivity, making it effective by rapidly absorbing and transferring heat. This PCM is ideally used in PCM-filled heat exchangers or panels within water heating systems. However, erythritol’s known higher melting point may limit its application in systems requiring phase change at lower temperatures. In contrast, paraffin wax and stearic acid, could be used encapsulated around water tanks to absorb and store heat, offer moderate thermal conductivity, which may affect rapid heat transfer but are suitable for maintaining consistent water temperatures.

Thank you to Oak Ridge National Lab and mentors for making this possible!